Our Craftsmanship

The production of a single Fionna piece is intricate and deliberate, requiring a keen attention to detail and an expert vision from start to finish. By sharing these insights into our process, we hope you gain a greater appreciation for the care and craftsmanship instilled in every piece of Fionna jewelry.

Design

The jewelry creation can be thought of as two key components: Design & Creation. Our process begins with design. In our opinion this is the most important step in the jewelry making process as it sets the vision for the pieces unique story.

Our in-house design team draws inspiration from the world we live in, creating designs that blend timeless and modern elements.

Our goal is to create designs that can accompany you throughout life's journey and can be cherished for generations.

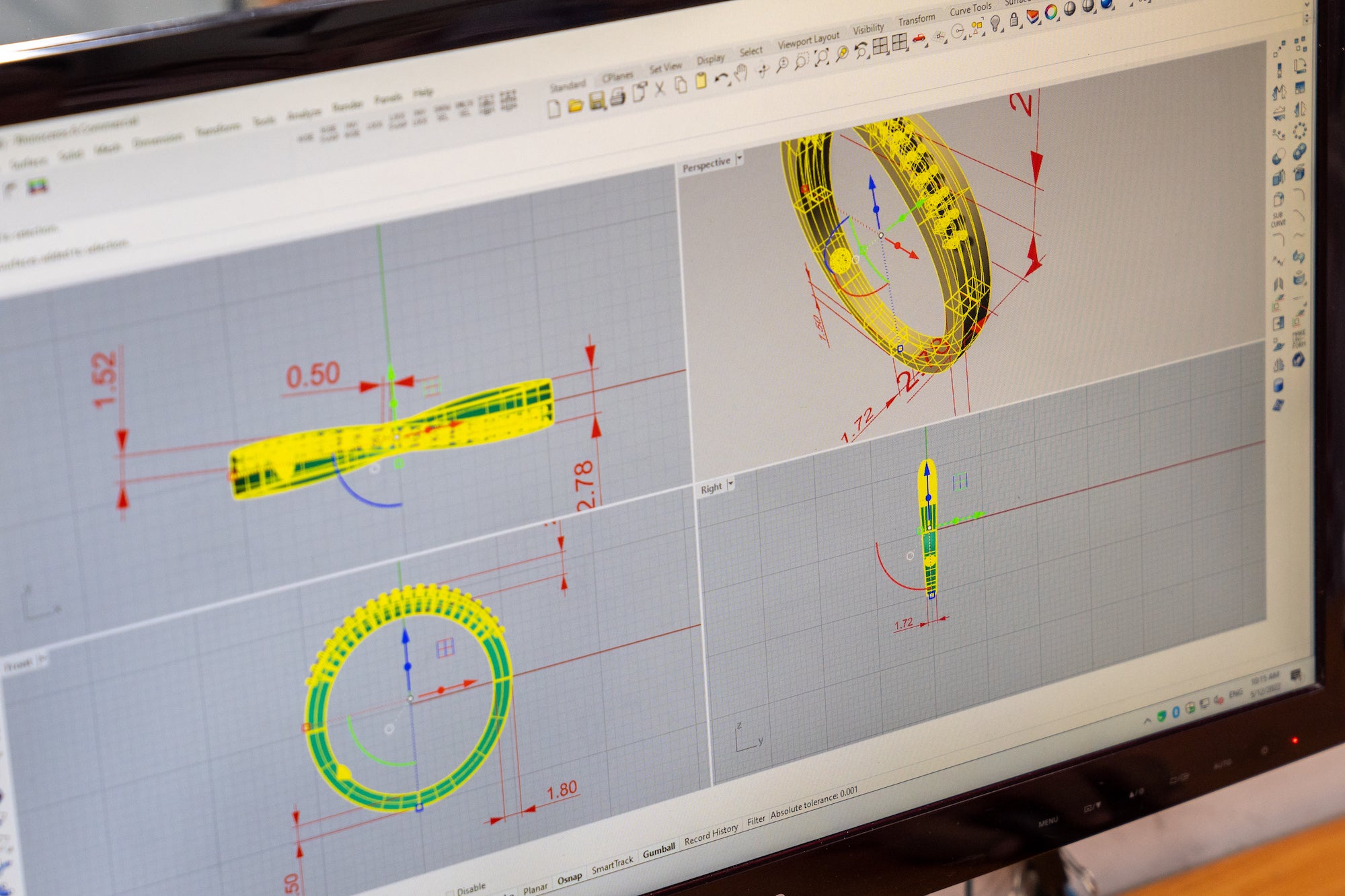

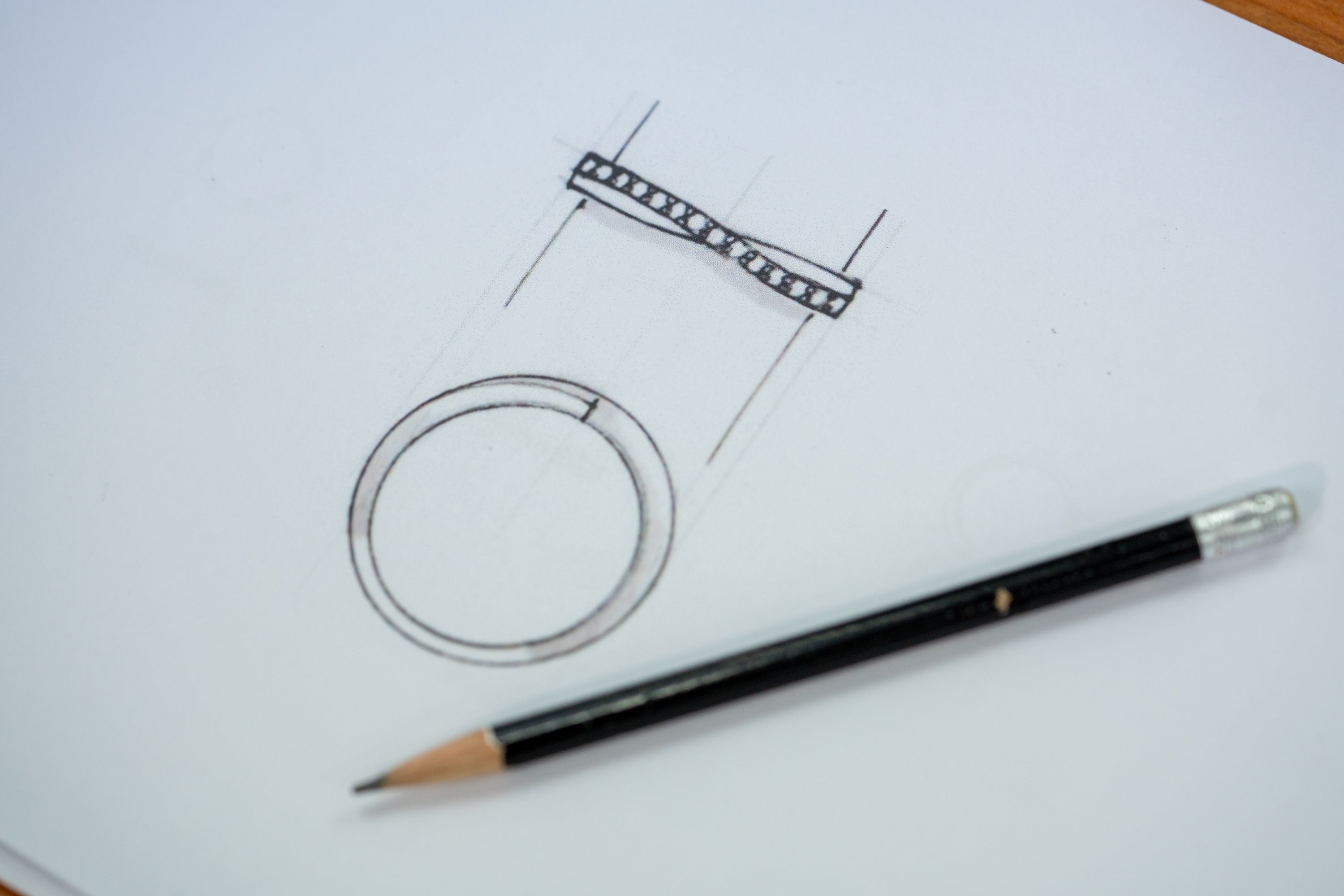

Once the inspiration is set, our team of designers sketches their ideas by hand, then recreates the design on a computer aided design program to create the design rendering.

Creation

The creation process is where our designs come to life. All of our jewelry is made by hand, and this is what makes every piece unique. Our skilled artisans carefully craft each piece fusing the traditional methods of jewelry making along with modern tools.

-

1. Master Model Creation

The art of making each piece by hand is the essence of our pieces and what makes them genuinely unique. From choosing the perfect natural gemstones to transforming them into a Fionna piece, our skilled artisans carefully execute each step.

The gemstones are genuinely cut and polished to suit each design, ensuring quality, beauty, and uniqueness in every piece. It is a labor-intensive process that showcases the skill and dedication of our team. From the intricate details to the overall quality, every piece of jewelry is crafted with love and attention to detail.Once the design rendering is completed, a prototype called a model is created. Our models are made by hand from our team of highly skilled model-makers.

-

3. Rubber Mold Creation

Once the model is complete, the next step in the jewelry making process is to create a rubber mold. The rubber mold enables us to make multiple copies of our items.

The rubber mold is created by cutting open a blank rubber mold and encasing the rubber around the master model. The frame will then be heated under pressure to vulcanize and cure the rubber around the imbedded model.

The result is a molded rubber that contains a negative impression of the model enclosed. Once the metal model is released, the mold-making step is completed by injecting pressurized molten wax through the sprue opening in the rubber mold. Once the wax cools, the rubber mold is peeled open to reveal a wax like that of the original jewelry model.

-

4. Casting

Our team of casters utilizes a “burn out” method of jewelry casting in which our wax models are connected to one another on a sprue to form a tree-like configuration. The “tree” is then suspended inside a metal flask and filled with plaster slurry.

After hardening and curing, flasks containing invested models are placed in specialized ovens, where the wax is incinerated at temperatures as high as 1600° F for 12 to 16 hours.

A properly burned-out flask will have no remaining residue of wax or resin, leaving behind a hollow impression left by the tree and sculptures that were burned from it. Once the hollow impression is created, our casters pour melted silver or gold into the flask, creating the actual piece of jewelry.

-

5. Polishing

Once the metal filled flask has cooled, the flask is dismantled and the jewelry pieces are prepared for polishing. Our polishers complete over 10 steps from start to finish to bring out the shine and lustrous finish of our pieces.

-

6. Final Quality Control Inspection

Each manufacturing stage utilizes a pod model whereby each stage has their own team managing everything.

Each manufacturing stage has their own quality control process and unique quality control specifications to ensure that when an item moves along the production process, it’s doing so having already been held to a high standard of quality.

Since so much emphasis is placed on quality control at both the beginning of the manufacturing process and during each stage, the rejection rate of items is virtually zero by the time the item goes to a final quality control check.

Quality above all else

Our workshop operates on a “quality in, quality out” manufacturing philosophy. The means our designers are immersed in every part of the manufacturing process to ensure the final product is a true reflection of their original concept.

Our carefully implemented processes and procedures mean team members work closely to ensure the integrity and quality of the design is also preserved, enabling us to create the highest-quality products in the shortest timeframe without compromise.

Down to the last detail

It’s important that your carefully selected Fionna piece arrives safely to your home.

We’ve reimagined our packaging to ensure it reflects our commitment to quality, down to the very last detail. Our specially crafted leather pouches are designed to be re-used when you’re travelling, out and about, or for storage of your pieces, ensuring they’re protected for years to come.